Our machinery organizes and injects fried products of small dimensions (donut holes).

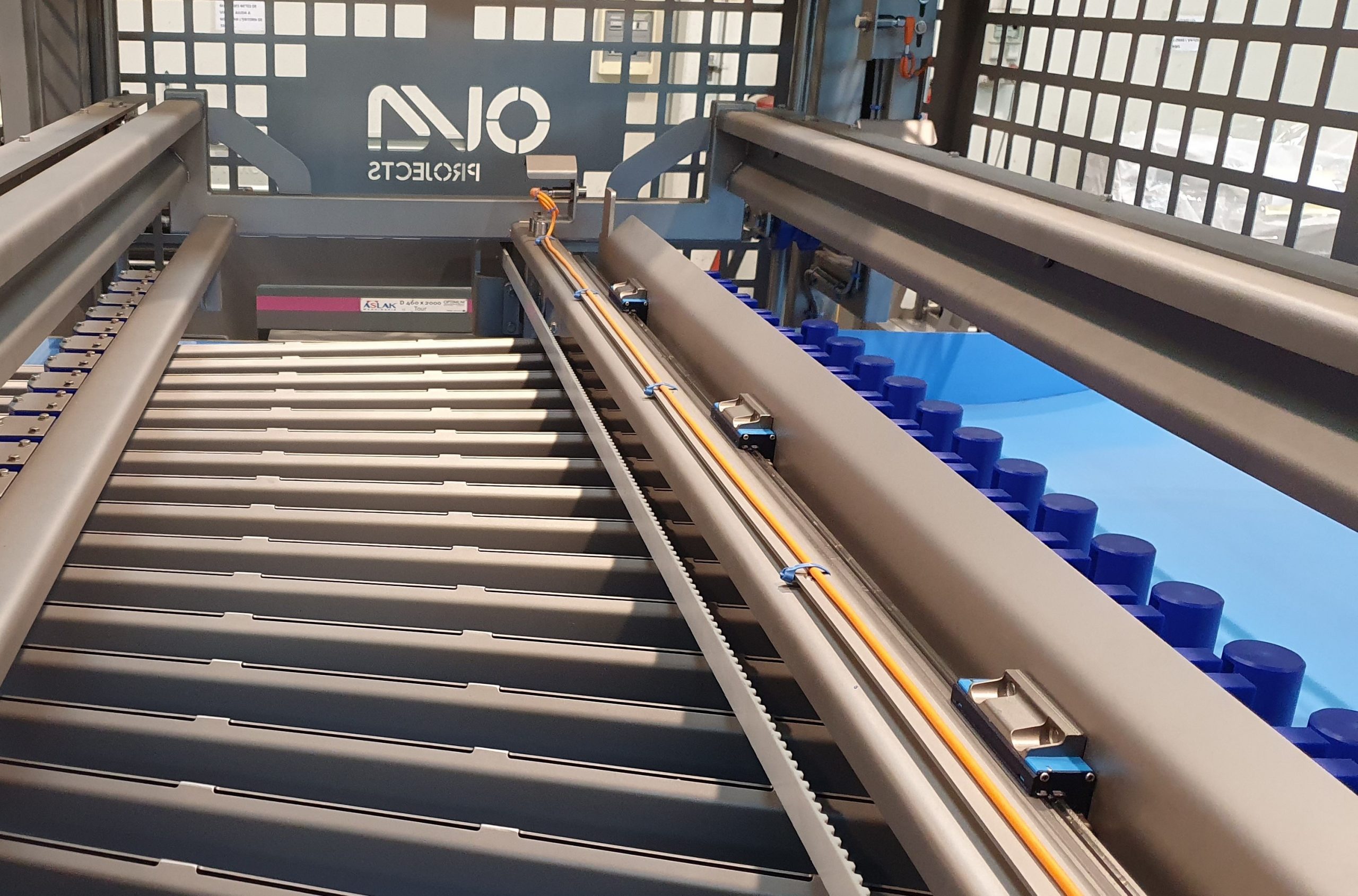

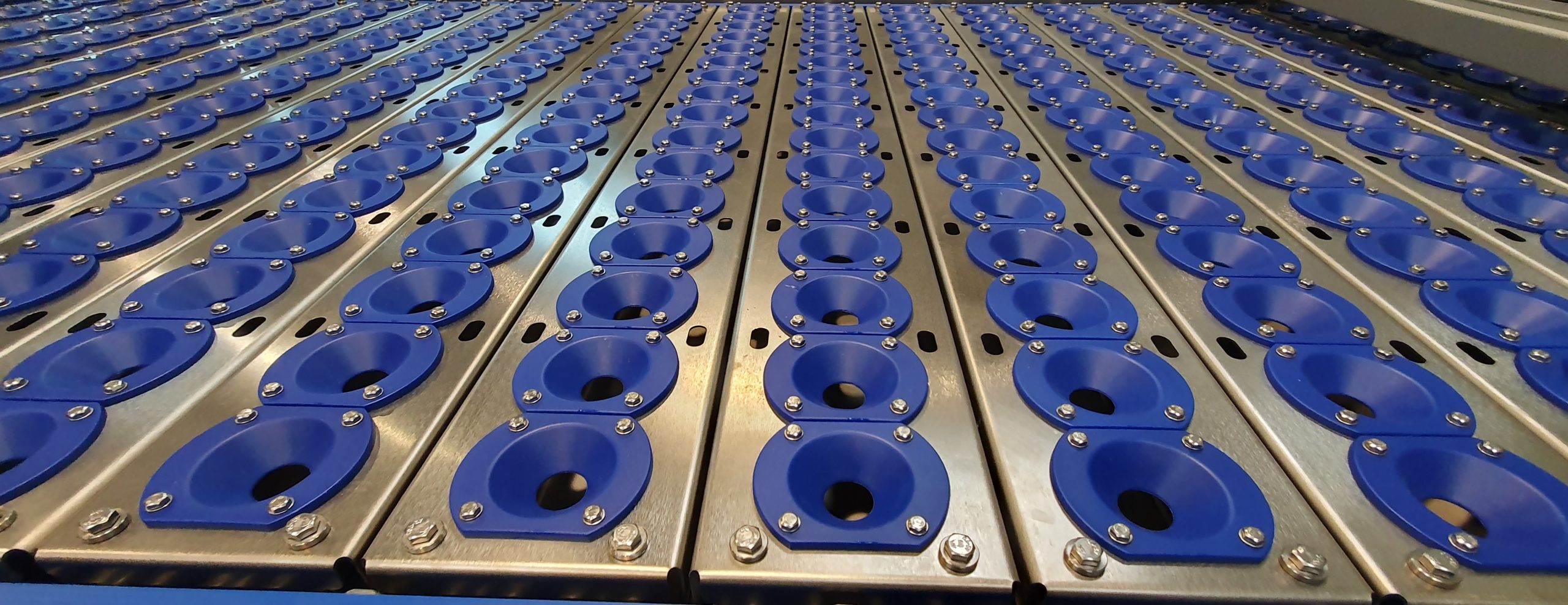

The special transport we have developed for this application, guarantees the ordering of the products and facilitates the quality of the injection.

The machinery, built to measure and adapted to the productive and hygienic needs of the Client, allows a productivity of up to 100,000 pieces per hour.

Optional:

- Independent dosing.

- Possibility of double flavor injection in the same product.

- Up to 40 cycles/minute of injection.

- Single or double chamber hopper with heating or cooling system.

- Pressurized manifold or pressurized hopper even with nitrogen.

- Manual or automatic washing C.I.P.

- Dosing in static or dynamic.

- Needles of different format and cut according to injection needs.